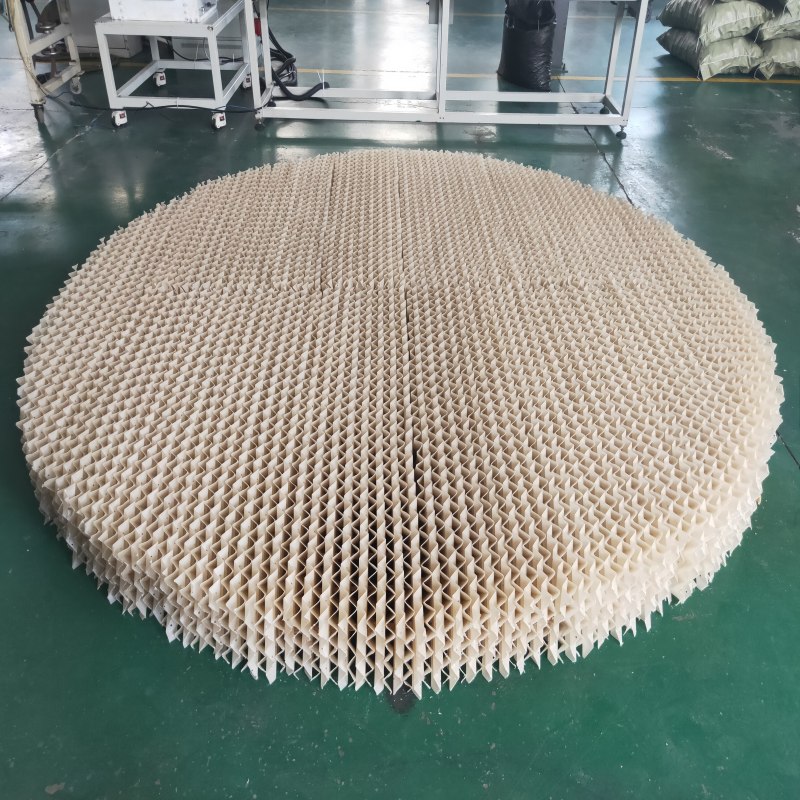

In highly corrosive environments such as concentrated sulfuric acid, hydrofluoric acid, and chlor alkali, the frequent failure of traditional metal/ceramic fillers has become a chronic problem in the industry - equipment downtime, increased maintenance costs, and disrupted production continuity. How to solve this stubborn disease? PVDF corrugated packing is becoming a key solution to replace traditional packing materials in fields such as chemical engineering, environmental protection, and wet metallurgy due to its excellent corrosion resistance.

? Advantages: Maintain near zero corrosion to 98% concentrated sulfuric acid, 40% hydrofluoric acid, concentrated alkali, and organic solvents (measured lifespan>10 years)

? Technical comparison: Corrosion resistant rolled 316L stainless steel, 5 times higher than PP/PE plastic, solves the risk of collapse and fragmentation of the filling layer, and provides dual effect empowerment in structural design

? Ripple topology optimization: gas-liquid distribution efficiency increased by 40%, pressure drop reduced by 35% (third-party flow field simulation data)

? Lightweight Revolution: With a density of only 1.78g/cm ³, reducing tower load by over 30% and improving seismic and crack resistance performance