What Is A Ceramic Raschig Rings Used For?

June 20, 2024

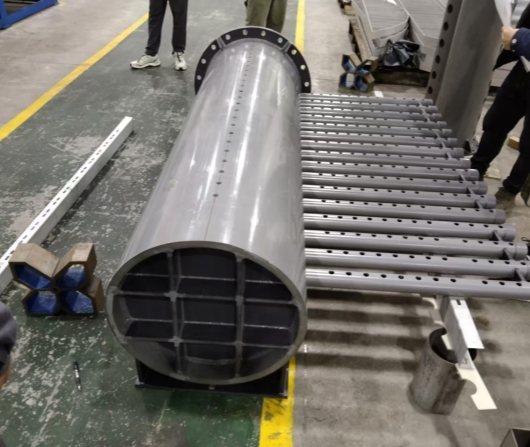

There is a sort of random packing known as ceramic Raschig rings that is used in chemical process towers and columns. These rings are comparable to their metal counterparts. Ceramic Raschig rings are fabricated from a wide variety of ceramic materials, including porcelain, alumina, and other refractory ceramics, along with additional substances.

Ceramic Raschig rings are comparable to those of metal Raschig rings in terms of both their design and their form. In terms of form, they are cylindrical, and their height is proportional to their diameter. The rings are arranged in a vertical stack inside the column, which results in a high interfacial area that facilitates the effective transfer of mass.

The model’s bulk weight ranges from

model

Bulk weight

15-16

750KG/m³

19-20

730KG/m³

25

700KG/m³

38-40

650KG/m³

50

600KG/m³

Raschig rings made of ceramic provide a number of benefits and are chosen in particular applications, including the following:

Ceramic materials offer a strong resistance to corrosion and chemical deterioration, making them a good choice for use in construction. As a result of their ability to tolerate hostile chemical conditions, Ceramic Raschig rings are appropriate for use in processes that include compounds that undergo corrosion.High temperature resistance: Ceramic rings are able to sustain high temperatures without experiencing considerable damage. It is common practice to use them in procedures that entail the application of high heat.

3. Thermal stability: Ceramic materials have a high level of thermal stability, which means that they are able to withstand sudden shifts in temperature without splitting or breaking. The presence of this feature is advantageous for operations that are subject to temperature variations.

4. Electrical insulation Ceramic materials that are electrically insulating may be helpful in applications that need electrical insulation because of their ability to insulate electrical current.

5. Lower cost: Ceramic Raschig rings are often more cost-effective than their metal equivalents, which is one of the reasons why they are the favored option in some applications.

Ceramic Raschig rings are often used in a variety of applications, including but not limited to distillation, absorption, stripping, gas scrubbing, and catalytic reactions. The advantages that they provide are comparable to those that metal Raschig rings offer, but they also have the additional benefit of being resistant to chemicals and stable at high temperatures.

The decision between ceramic Raschig rings and metal Raschig rings is determined by the unique needs of the process. These criteria include the chemical composition of the substances that are being processed, the temperatures at which the process is being carried out, and budgetary concerns.

Applications of ceramic Raschig rings include:

Raschig rings made of ceramic are used in a variety of chemical engineering and industrial operations, including the following situations:

1. Distillation: Ceramic Raschig rings are often used in distillation columns primarily for the purpose of random packing. By facilitating the effective movement of mass between the liquid and vapor phases, they contribute to the overall process of facilitating the separation of components depending on their respective boiling points.

2. Absorption: Ceramic Raschig rings are used in absorption operations in order to improve the point of contact between a gas stream and a liquid absorbent. Because of this, it is possible to move one or more components from the gas phase to the liquid phase for the purpose of purification or separation.

3. Stripping: Ceramic Raschig rings may be used in the process of stripping or desorption in order to remove volatile components from a liquid stream. When a stripping gas or vapor is passed through a column that is packed with ceramic rings, it is possible to assist effective mass transfer, which ultimately results in the removal of components that are not needed.

4. Gas scrubbing: Ceramic Raschig rings are versatile enough to be used in gas scrubbing applications, which include the removal of pollutants or impurities from a gas stream. The rings provide a high surface area that allows for close contact between the gas and a liquid cleansing solution. This makes it possible for the pollutants to be effectively absorbed or chemically reacted.

5. On the subject of catalytic reactions, Raschig rings made of ceramic may be exploited as catalyst support structures in specific catalytic reactions. The rings provide a large surface area for the deposition of catalytic materials, which contributes to the promotion of the chemical processes that are required.

6. Heat transfer: Ceramic Raschig rings are used as a medium for heat transmission in a number of different applications. The rings improve the effectiveness of heat transmission inside a heat exchanger or reactor by increasing the surface area of the device. This makes it possible for thermal operations to be carried out effectively.

It is essential to keep in mind that the selection of Ceramic Raschig rings for a particular application is contingent upon a number of factors, including the chemical compatibility of the ceramic material with the process streams, the operating temperatures, the pressure conditions, and the desired efficiency of mass transfer or heat transfer.

Raschig rings made of material made of ceramic:

Ceramic Raschig rings may be fabricated from a wide variety of ceramic materials, the selection of which is contingent on the particular application and the specifications of the desired process. Some examples of common ceramic materials that are utilized in the production of ceramic Raschig rings are as follows:

1. Alumina (Al2O3): Ceramic Raschig rings made from alumina are very popular because of their superior chemical resistance, stability at high temperatures, and mechanical strength. They are able to tolerate severe chemical conditions and are suited for a wide variety of applications with similar requirements.

2. Porcelain: To create porcelain ceramic Raschig rings, a combination of clay, kaolin, and feldspar is used in the manufacturing process. They have a high level of chemical resistance and are often used in applications that must be carried out in environments with moderate temperatures and circumstances that are corrosive.

3. Silicon carbide (SiC) is the third material on the list. The extraordinary thermal stability and resilience to high temperatures that ceramic Raschig rings possess have earned them a distinguished reputation. The majority of the often, they are used in applications that are subjected to exceptionally high temperatures and harsh chemical conditions.

4. Zirconia (ZrO2): Ceramic Raschig rings made of zirconia material provide exceptional resistance to thermal stress and stability at high temperatures. These materials are excellent for use in applications that need resistance to thermal cycling as well as fast temperature variations.

5. Ceramic composites: Ceramic Raschig rings may be constructed from composite materials in some circumstances. This involves blending several ceramic compositions in order to attain certain qualities. In order to offer better chemical resistance, mechanical strength, or any other desirable features, these composites may be customized to meet specific requirements.

The selection of a ceramic material for Raschig rings is contingent upon a number of parameters, including the particular application, the chemical composition of the process streams, the operating temperatures, the pressure conditions, and the performance requirements that are sought. The selection of a ceramic material that is capable of withstanding the circumstances of the process and that offers the required chemical resistance, thermal stability, and mechanical strength for the application in question is of utmost importance.

Ceramic Raschig rings are particularly useful for a wide range of applications in chemical engineering and industrial processes due to the fact that they possess a number of significant characteristics. Notable characteristics of Ceramic Raschig rings include the following:

1. Ceramic materials that are utilized in Raschig rings, such as alumina, porcelain, or silicon carbide, have good chemical resistance. This is one of the defining characteristics of these materials. As a result of their ability to tolerate corrosive and hostile chemical conditions without experiencing considerable deterioration, they are excellent for applications that include acids, alkalis, and other compounds that are aggressive to corrosion.

2. Resistance to high temperatures: Ceramic Raschig rings are well-known for their capacity to tolerate temperatures that are very high. High-temperature stability is shown by them, and they are able to function in applications that are subjected to circumstances of extreme temperatures without suffering a major loss of their chemical or physical characteristics. Because of this, they are appropriate for operations that involve the transmission of heat, reactions that take place at high temperatures, or thermal cycling.

3. High mechanical strength Ceramic Raschig rings have a high mechanical strength, which enables them to endure high pressures and mechanical stresses that are often encountered in industrial operations. The structural integrity of its construction may be preserved even when subjected to rigorous working circumstances.

4. When it comes to thermal shock resistance, the ceramic materials that are used in Raschig rings often demonstrate exceptional thermal shock resistance. They are able to resist sudden changes in temperature without cracking or breaking any of its components. The significance of this feature cannot be overstated in the context of operations that include temperature cycling or in situations where rapid temperature changes may occur.

5. Electrical insulation Ceramic materials that are electrically insulating may be helpful in applications that need electrical insulation because of their ability to insulate electrical current. Ceramic Raschig rings are appropriate for use in procedures that include electrical equipment or in situations where electrical separation is required because of this property.

6. Ceramic Raschig rings are often more cost-effective than their metal counterparts, which makes them an inexpensive alternative for some applications. This is because ceramic Raschig rings are made of ceramic. Because they are able to provide the required performance at a cost that is substantially lower, they are appealing to industries that are searching for solutions that are both efficient and relatively inexpensive.

Seventh, the availability of a variety of sizes and forms Ceramic Raschig rings are available in a wide range of sizes and shapes, which enables flexibility in design and optimization for particular process needs. Individualization is made possible by the variety of alternatives, which allows for the achievement of the required mass transfer efficiency and pressure drop characteristics.

The combination of these characteristics makes Ceramic Raschig rings appropriate for a broad variety of applications, including as the processes of distillation, absorption, stripping, gas scrubbing, catalytic reactions, and heat transmission.

Read More

Address : Intersection of Jinguang Avenue and Chongqing Middle Road, Anyuan Industrial Park, Anyuan District, Pingxiang City, Jiangxi

Address : Intersection of Jinguang Avenue and Chongqing Middle Road, Anyuan Industrial Park, Anyuan District, Pingxiang City, Jiangxi Tel :

Tel :  Email :

Email :  WhatsApp :

WhatsApp :  IPv6 network supported

IPv6 network supported